“OUR KEY PRODUCTS ARE

reinforcing steel bar series products.”

STEEL GRATING, BAR GRATING

At JinDing, we focus on concrete reinforcing steel bar, ribbed steel bar, deformed bar, round or square bar, reinforcing mesh, steel fiber, steel bar grating, angle steel and series steel materials for construction application.

- Home

- Product Center Reinforcing Steel PC Strand

Reinforcing Steel PC Strand

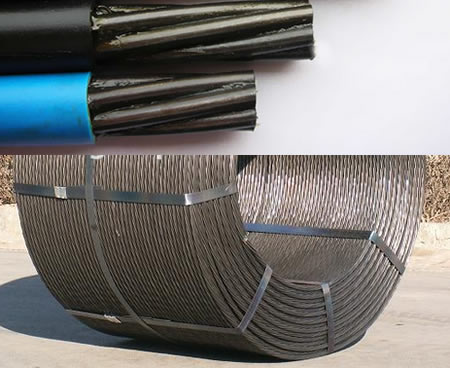

Multi-wire Stranding structures Enables PC Strand Ideal Elements for Large Span Concrete Constructions

PC strands are popular in concrete building as low relaxation and high strength combined steel wire units for concrete reinforcing. The multi-wire structure enables a great strength in concrete pre-stressing. The strand length of 1800mm to 3600mm enables longer span structure construction, makes thinner and lighter elements with a reduction in number of piles. Using pc strands also saves consumption of energy in freight and handling. Especially for large-span concrete constructions in bridges, railway, highway, coal mine, stadiums and multi-storey buildings.

Common strand section profiles include 1x2, 1x3, 1x7 wire structures. Popular strands we offer are 1x7 wire structure unbounded pc steel strands: Diameter 12.7mm 7 wire strands, 15.20mm 7 wire, 15.24mm 7 wire and 15.70mm 7 wire. Weight ranges from 2MT to 4MT. Steel rod materials for processing of PC strands are high carbon steel 77B and 82B. Tensile strength can be 1670Mpa, 1770Mpa, 1860Mpa optional.

Technical Treatment in Production to Ensure Proper Using with Concrete:

The pc strands are made of continued drawing with large deduction stranding then stabilizing treatment;

The carbon steel materials have high rate of yield strength and ultimate strength, Low relaxation;

Steady modulus of elasticity, stress relieved in production, highly fixed with Concrete.

General Technical Information of P. C. Strands:

Structure: 1x7 wire, 1x2 wire,1x3 wire,1x19 wire

Property: Low Relaxation, High Tensile strength

Common type: Unbonded

Materials: Cold drawn steel wire

Tensile Strength: 1470Mpa ~ 1960Mpa

Yield Strength: 1320Mpa ~ 1760 Mpa

Elongation: Not less than 3.5%

Initial Load: Not more than 70%

Relaxation(1000h):No more than 2.5%

Strand Diameter Available: 9.53mm, 12.7mm, 15.2mm, 15.7mm, 17.8mm, 21.8mm

Packing Details: Standard Export Package (Wrapped by steel strips, waterproof cloth sheet, wooden pallet)

Standards: Following international standards in production of PC Strand: GB/T5224 (China Standard), ASTMA416, ASTMA421 (USA), BS5896(UN), JIS3536(Japan), AS/NZS4672(Australia), NBR-7483(Brazil), EN10138(Europe), ISO6934.

Uses: Mainly used as building material reinforcing strand for concrete structures such as Bridge Beam, Mining anchoring, Slope reinforcement, Dam reinforcement, offshore oil platform, Nuclear power plant, railway sleeper, bridges, railway station and multi-floor buildings.

Specifications of 1x7 Wire Structure Pre-stressed Concrete Strand:

| Specifications | Tensile Strength (Mpa) |

Section Area (mm2) |

Grease Mass Per Meter (g/m) |

Minimum Thickness of Coat (mm) |

Friction Factor (ц) |

Effect Modulus (k) |

Mass per Meter (kg/m) |

| 1*7-Ф12.70 | 1720 1860 1960 |

98.7 | 43 | 1.0 | 0.04-0.1 | 0.003-0.004 | 0.875 |

| 1*7-Ф15.20 | 1570 1670 1770 1860 1960 |

140.0 | 50 | 1.21 | |||

| 1*7-Ф15.24 | 1860 | 140.0 | 50 | ||||

| 1*7-Ф15.70 | 1860 | 150.0 | 53 | 1.30 |

We are listing in the following tables technical details of PC strands meeting different standards.

| P. C. Strand Meeting Standard ASTM A 416: | |||||||||

| Grade | Normal Diameter (mm) |

Tolerance (mm) |

Area of section (mm2) |

Theoretical Weight per 1000 metre |

Minimum breaking strength (KN) |

Minimum load At percent extension (KN) |

Elonga- tion (%) |

Relaxation after 1000hrs at |

|

| Initial Load 70% |

Initial Load 80% |

||||||||

| 250 | 9.53 | +/-0.40 | 51.61 | 405 | 89.0 | 80.1 | 3.5 | 2.5 | 3.5 |

| 11.11 | 69.68 | 548 | 120.1 | 108.1 | |||||

| 12.70 | 92.90 | 730 | 160.1 | 144.1 | |||||

| 15.24 | 139.35 | 1094 | 240.2 | 216.2 | |||||

| 270 | 9.53 | +0.65 | 54.84 | 432 | 102.3 | 92.1 | 3.5 | 2.5 | 3.5 |

| 11.11 | -0.15 | 74.19 | 582 | 137.9 | 124.1 | ||||

| 12.70 | 98.71 | 775 | 183.7 | 165.3 | |||||

| 15.24 | 140 | 1102 | 260.7 | 234.6 | |||||

| P.C. Strand Meeting Standard BS5896 | ||||||||

| Strand type |

Normal Dia. MM |

Tensile strength (Mpa) |

Specified breaking load (KN) |

Load at 1% Elongation (KN) |

Minimum Elongation at max load-1% |

Relaxation Value 1000h | ||

| Initial | Initial | Initial | ||||||

| Load 60% |

Load 70% |

Load 80% |

||||||

| 7-wire standard | 9.3 | 1770 | 92 | 81 | 3.5 | 1 | 2.5 | 4.5 |

| 11 | 1770 | 125 | 110 | |||||

| 12.5 | 1770 | 164 | 144 | |||||

| 15.2 | 1670 | 232 | 204 | |||||

| 7-wire super | 9.6 | 1860 | 102 | 90 | 3.5 | 1 | 2.5 | 4.5 |

| 11.3 | 1860 | 139 | 122 | |||||

| 12.9 | 1860 | 186 | 163 | |||||

| 15.7 | 1770 | 265 | 233 | |||||

| 7-wire drawn | 12.7 | 1860 | 209 | 184 | 3.5 | 1 | 2.5 | 4.5 |

| 15.2 | 1820 | 300 | 255 | |||||

| 18 | 1700 | 380 | 323 | |||||

JISG 3536 Standard PC Strand Shall Meet the Following Specifications:

| Strand Type | mm Nominal Diameter | mm Diameter Tolerance | mm2 Nominal Area |

KG/1000m Nominal Weight | KN Min. Breaking Strength | KN Min. Yield Strength | Min. Elongation at Max Load | Relaxation | |

| Initial Load Of Min Nominal Breaking Strength | 1000h Value No More Than | ||||||||

| 15-7AN | 9.3 | +0.4 -0.2 |

51.61 | 405 | 88.8 | 75.5 | 3.50% | 70% | 2.50% |

| 10.8 | 69.68 | 546 | 120 | 102 | |||||

| 15-7AL | 12.4 | 92.9 | 729 | 160 | 136 | ||||

| 15.2 | 138.7 | 1101 | 240 | 204 | |||||

| 15-7BN | 9.5 | 54.84 | 432 | 102 | 86.8 | ||||

| 11.1 | 74.19 | 580 | 128 | 118 | |||||

| 15-7BL | 12.7 | 98.71 | 774 | 183 | 156 | ||||

| 15.2 | 138.7 | 1101 | 261 | 222 | |||||

| 15-19W 15-19L | 17.8 | +0.6 -0.25 |

208.4 | 1652 | 387 | 330 | |||

| 21.8 | 312.9 | 2482 | 573 | 495 | |||||

| 28.6 | 532.4 | 4229 | 949 | 807 | |||||

AS 1311 Standard PC Shall Meet the Following Specifications:

| Type | mm Nominal Diameter | mm Diameter Tolerance | mm2 Nominal Area | KG/1000m Nominal Weight | Min. Breaking Strength | Min. Yield Strength | mm Min. Elongation at Max Load | Relaxation | |

| Initial Load Of Min Nominal Breaking Strength | 1000h Value No More Than | ||||||||

| Common Strand | 9.3 | ±0.4 | 52 | 410 | 94 | 85%Min Breaking strength |

3.50% | 70% 80% |

2.5% 4.5% |

| 10.9 | 71 | 555 | 125 | ||||||

| 12.7 | 93 | 740 | 165 | ||||||

| 15.2 | 139 | 1090 | 227 | ||||||

| 18 | 199 | 1560 | 311 | ||||||

| Supper Strand | 9.3 | ±0.4 | 55 | 430 | 102 | ||||

| 10.9 | 75 | 590 | 138 | ||||||

| 12.7 | 100 | 785 | 184 | ||||||

| 15.2 | 143 | 1125 | 250 | ||||||

| 18 | 199 | 1560 | 338 | ||||||

| Extra- high tensile steel strand |

15.2 | ±0.4 | 143 | 1125 | 261 | ||||

OUR PRODUCTS

» Rebar Cages

» Steel Bar Gratings

» Reinforcing Bar

» Rebar Couplers

» Steel Reinforcement Mesh

» Concrete Reinforcement Steel Bar

» Concrete Reinforcing Mesh

» Ribbed Steel Bar Welded Mesh

» Reinforcing Steel PC Strand

» Round Steel Bar

» Hot Rolled Ribbed Steel Bar

» Deformed Steel Bar

» Hot Rolled Steel Plate

» Square Steel Bar

» Cold Rolled Steel Bar

» H Beam Steel

» Channel Steel Bar

» U Channel Steel Bar

» I-Beam Steel

» Steel Bar Supports

» High Chairs Wire Spacer

» Reinforcing Steel Bar Chair

» Slab Bolsters/ Beam Bolsters

» Plastic / Polyethylene Rebar Supports

» Equal Angle Steel

» Angle Steel Bar

» Spiral PC Wire

» Steel Fiber

» Steel Bar Welding Machine

» Deformed Reinforcing Steel Bar Weight

» Low Cobalt Stainless Steel Bar

» Formwork Rib Lathe