“OUR KEY PRODUCTS ARE

reinforcing steel bar series products.”

STEEL GRATING, BAR GRATING

At JinDing, we focus on concrete reinforcing steel bar, ribbed steel bar, deformed bar, round or square bar, reinforcing mesh, steel fiber, steel bar grating, angle steel and series steel materials for construction application.

- Home

- Product Center Rebar Cages

Steel Bar Reinforcement Cages

Reinforcing steel bar cages, also called rebar cages, pile reinforcing cages, are circular mesh pads made of carbon steel bar by welding process into cage-shaped steel skeletons used in the pre-casting production of pits, covers and tunnels for reinforcement or to strengthen tendons of location bars. The pile cages are especailly used in oil industry for sub marine construction of oil conveying pipes projects. We supply steel bar pile cages with a variety of cage pitch, hoop diameter, wire numbers and length.

Reinforcing Cage Designs: The pre-welded rebar cages are supplied in piles, pads, columns and other shapes to meet specific uses. We have advanced high efficiency welding machine to produce high quality pile reinforcing mesh cages to meet specific requirements of the project needs.

Black Steel Rebar Cages for Pole Foundation

Welded rebar cages and mats reinforcement can be supplied in black steel ranging from 8 inch to 60 inch diameter and the length can be 60 feet. The welded rebar reinforcement is used to replace the wire tied rebar reinforcing structure with its advantage. Welded rebar cage provide a rigid and strong structure with rebars maintaining in the correct locations during transportation and in practical use.

High-strength Pile Reinforcement Cages for Sea Projects

Spiral rebar cage is used to ensure the transverse force of the pile. Its density has a crucial role to prevent the pile case from cracking. Iron steel rebar cages designed using rebar with square rebar links spaced at 200mm centres, for underground sea projects.

Using of Main Rebar and Pile Cages:

A, Combine the main rebar first and then the pile cage, that is to say, butt weld the rebar of 9m length together to 9-27 meters and then use the pilemaster to longer pile cage.

B, Combine the pile cage and then the main rebar, first make the pile cage of 9m or 12m of standard. And then weld the short pile cages to longer pile cages.

C,

To get the double rebar pile cages to improve work efficiency, normally we suggest welding the second bar after the pile cage is formed.

D, For the inner reinforcing bar, we supply the rebar bending machine to reinforcing the stirrup. Compare to weld rebar structure, the difference is the rebar ends do not bond together, hence easier to install.

Rebar Mesh Cage Specification Scope:

| Diameter of welded frame | ø250-ø1200 |

| Length of welded reinforcement cage | 4M-15M |

| Number of longitudinal reinforcement steel bar | 6, 7, 10 , 12, 14, etc |

| Diameter of longitudinal reinforcement rebar | ø7.1, ø9.0, ø10.7, ø12.6MM |

| Diameter of hoop reinforcement | ø4- ø6 |

| Cage pitch | 0-100mm |

Rebar Cages are pre-assembled frameworks of reinforcing bars (rebars) used to reinforce concrete structures such as columns, beams, foundations, piles, and slabs.

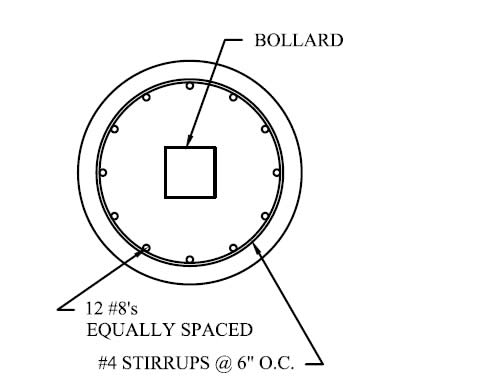

Cylindrical Rebar Cages 2ft 6in Diameter

Cage length: 6 ft 6in

Delivery for India

Rebar types: Deformed bars ASTM A615 Grade 60

Diameter range: 8–40 mm

Components:

Rebar

Bollard /Vertical post

Stirrups / ties

Design:

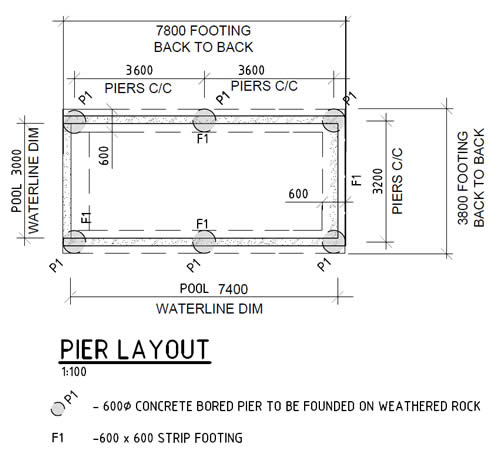

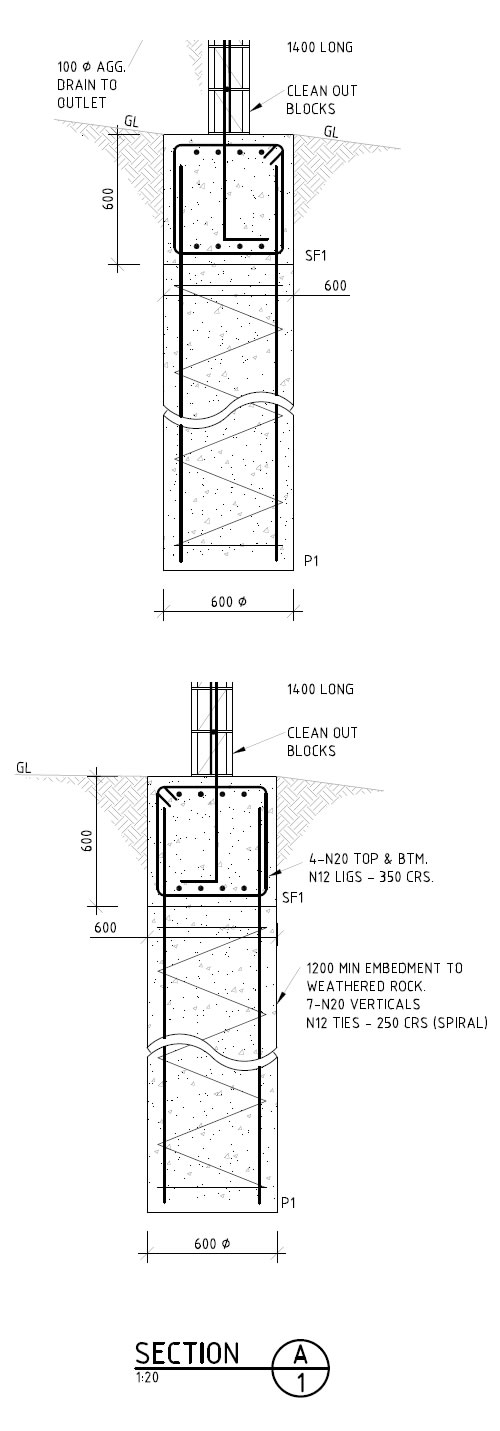

Rebar Cages for Construction - Australia Project

Cages details:

Rebar cages for 7 structural piers

Rebar cages for column strip footings.

Drawings reference:

Pile Reinforcement Cages (Straight Bars and Helical)

Specification:

600 diameter piles

Grade B500B, BS4449:2005, straight bars and helical

8H40 x 13.0m plus H10@200mm cc

Debonding foam to 1m

Supplied with:

50mm Skid spacers

Lifting bands

Reinforcing Cage 4EA 5 Rebar 42" Verticals ASTM A615, GRADE 60

SPECIFICATIONS FOR REINFORCING CAGE

4EA, 5 Rebar 42" verticals

Reinforcing steel conforms to ASTM A615, GRADE 60

Reinforcing cages for footings

Assembling methods:

Assembled with 3 circular ties spaced at 9"

Assembled with one continuous # 3 spiral tie

All reinforcing cages to be tied with appropriate wire, not welded

Shall include plastic centralizers and chairs on vertical bars to properly center the reinforcing in each drilled hole.

Prefabricated Steel Reinforcement Cages

Reinforcement cages for ground beam

Supplied with spacers, tying wire to install the ground beam reinforcement cage before pouring concrete.

Specification:

Steel Reinforcement cut and bent in accordance with BS8666

Reinforcement steel to be high yield grade 500. in accordance with BS4449.

Steel REBAR Cage (One open end)

Custom made Rebar Cage (One open end)

Specification: 35x35x75 cm

Frame: Steel rectangular bar 30 x 30 mm, rebar diameter:10 mm

Custom made ebar Cage (Both ends open)

Specification: 35x35x90 cm

Frame: Steel rectangular bar 30 x 30 mm, rebar diameter:10 mm

Cages capabale of withstanding a 600 PSI burst

PROCESS:

Truss Cage Processing

1.Raw material selecting

2.Cutting and bending of steel bars

3. Welding mesh of different phases of the trusses for the rebar cages

Notes:

- 1. Associated reinforcement drawing: 1MC04-SCJ_SDH-TN-DDE-SS05_SL06-334301.

- 2. All weldings shall be carried out according to BS EN ISO 17660

- 3. Shear factor SF30 for welded meshes according to EN ISO 17660-1

- 4. Shear factor SF70 for anchorage bars according to EN ISO 17660-1

- 5. Reinforcement to be cut locally in the zones wheres clashes with pockets occur. Any bar cutting beyond what is shown shall be raised with the Designer for their approval.

- 6. For further information about materials and welding refer to general notes.

Reinforcement to be cut locally in the area of the bolt pockets.

| Steel List | |||

| Type | Length | Diameter | Weight/Piece |

| Transverse Reinforcement | 1824mm | 8mm | 0.72 kg |

| Bending Reinforcement | 3924mm | 10mm | 2.42 kg |

| Steel List | |||

| Type | Length | Diameter | Weight/Piece |

| Transverse Reinforcement | 1824mm | 8mm | 0.72 kg |

| Bending Reinforcement | 4145mm | 10mm | 2.56 kg |

Rebar Cage Tunnel Construction

Steel Rebar Reinforcement Cages for Tunnel Rings Concrete Segment

Sets of Rebar Reinforcement Cages made of Steel bars of Ø8 mm across and bent Steel bars of Ø10 mm along the set

Length of rebars across cage 1824 mm, steel bars along cage between 3924 mm and 4145 mm.

Rebar cages General Requirement

Manufacturing and supply of REBAR REINFORCEMENT CAGES for tunnel rings concrete segments according technical characteristics detailed below:

- Rebar steel: B 500B, according to EN 1992 Section 3.2 and BS 4449:2005+A2:2009

- Meshes fabricated with a shear factor SF30 according to EN ISO 17660-1

- Anchorage bars of meshes in intrados to be welded with a shear factor SF70 according to EN ISO 17660-1.

- Ladders for bursting reinforcement on circumferential and longitudinal joints to be fabricated with a shear factor SF70 according to EN ISO 17660-1.

Raw material: rebar or coils.

Cutting and bending of bars, trusses, spacers, ladders

Assembly of segment cages

QUALITY STANDARD

Rebar steel grade: B500B according to EN 1992 Section 3.2 and BS 4449:2005+A2:2009

Meshes to be fabricated with a shear factor SF30 according to EN ISO 17660-1

Anchorage bars of meshes in intrados to be welded with a shear factor SF70 according to EN ISO 17660-1.

Ladders for bursting reinforcement on circumferential and longitudinal joints to be fabricated with a shear factor SF70 according to EN ISO 17660-1.

Trial rebar cages to be produced in the formwork before production.

Position of individual bars may change.

All welding carried out according to BS EN ISO 17660 and EN ISO 17660-1.

Shear factor of SF30 for welded meshes

Shear factor of SF70 for anchor bars

Shear factor of SF70 for ladders

Types and Specification of Reinforcement Steel Cages for Concrete Segments

Rebar Cage Types:

Standard Ring Rebar Cages

Rebar Cages Passage Segment

Rebar Cages Compensation Segments

Rebar Cage Cross Passage Segment

Rebar Cage Ventilation Shaft Segment

Cage Shaft Passage Segment

DELIVERIES

Steel frames to be embedded into the rebar cage structure and the complete set of rebar + steel frame should be placed as single unit into the mould.

Designed rebar cage is a partly welded cage.

The solution can be changed into a fully welded cage with some savings in rebar quantities.

Different tolerances and different quality of welding seams may apply.

Rebar cages are delivered with following data:

Type of ring, segment and rebar

DOCUMENTATION

The documentation to be provided by the Supplier is as follows:

- Test Results of Raw Material traceability, Milling Certificates, according to standard EN 1992.

- Certificates of Quality

- Results of Mechanical Properties of the material, as requested in the design plans and specifications.

- Other documents related.

OUR PRODUCTS

» Rebar Cages

» Steel Bar Gratings

» Reinforcing Bar

» Rebar Couplers

» Steel Reinforcement Mesh

» Concrete Reinforcement Steel Bar

» Concrete Reinforcing Mesh

» Ribbed Steel Bar Welded Mesh

» Reinforcing Steel PC Strand

» Round Steel Bar

» Hot Rolled Ribbed Steel Bar

» Deformed Steel Bar

» Hot Rolled Steel Plate

» Square Steel Bar

» Cold Rolled Steel Bar

» H Beam Steel

» Channel Steel Bar

» U Channel Steel Bar

» I-Beam Steel

» Steel Bar Supports

» High Chairs Wire Spacer

» Reinforcing Steel Bar Chair

» Slab Bolsters/ Beam Bolsters

» Plastic / Polyethylene Rebar Supports

» Equal Angle Steel

» Angle Steel Bar

» Spiral PC Wire

» Steel Fiber

» Steel Bar Welding Machine

» Deformed Reinforcing Steel Bar Weight

» Low Cobalt Stainless Steel Bar

» Formwork Rib Lathe